Advisor: Dr. Pelegri

Lab Members involved: Luis Rafael Miranda Rodriguez

Abstract:

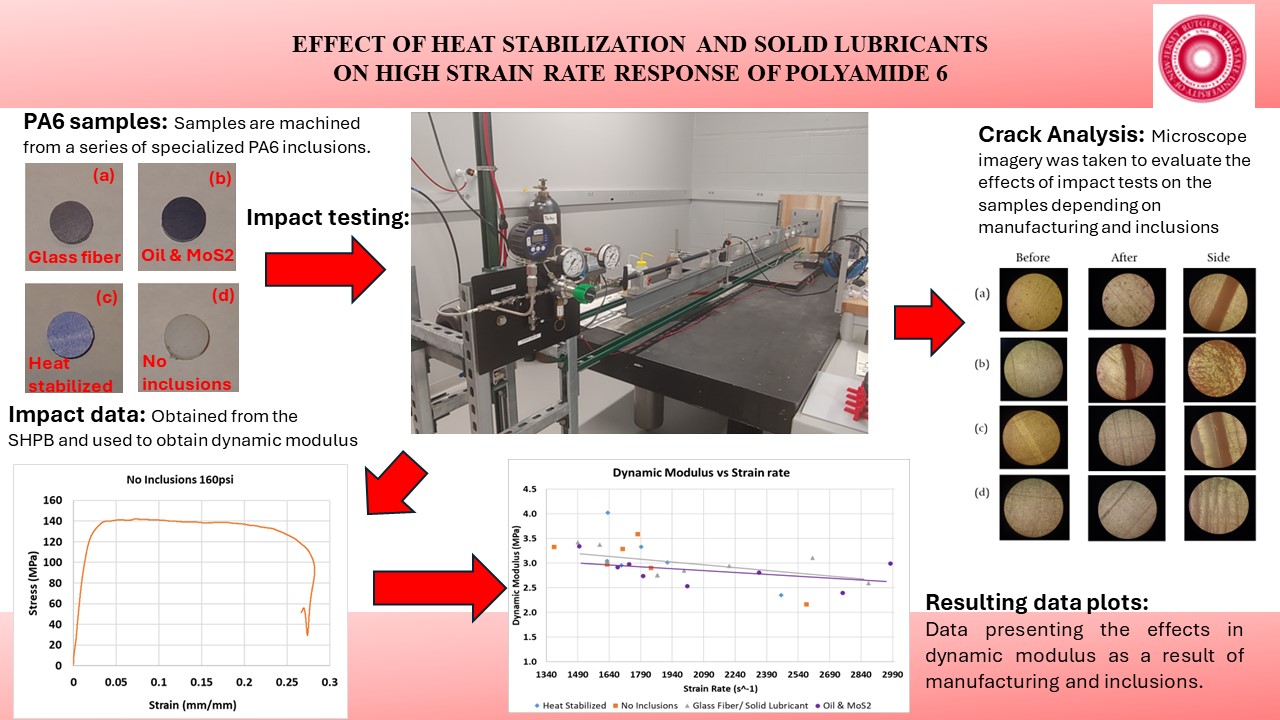

Impact properties on polymeric materials tend to behave differently depending on processing and inclusions. It is

interesting to modern science to evaluate how these processes and inclusions can help to enhance polymers in

extreme scenarios. Thus, one such polymeric material, Polyamide 6 (PA6), is studied using different processing

methods under impact testing. Several categories of PA6 composites were analyzed, including neat, heat-stabilized,

oil and molybdenum disulfide-doped (oil & MoS2), and glass fiber solid lubricant-doped. The analysis was

performed using an in-house Split Hopkinson Pressure Bar and computational analysis. It was found that PA6 with

inclusions was more capable of maintaining dynamic modulus. In contrast, rapid deterioration of dynamic modulus

was found in those that did not have inclusions when evaluated at an increased strain rate. The cracking of samples

started at the 1900s-1 strain rate, and the shattering of samples did not occur until the 2300s-1 strain rate. In the end,

it was observed that adding inclusions assisted in the hardening of samples at higher strain rates.